The temperature at the heart of your HACCP controls

Contents

Temperature and cold chain monitoring is an essential component of your HACCP. Your health control plan requires you to perform multiple temperature controls at multiple stages. However, you prefer to concentrate on your job and your expertise. That’s why you need reliable tools that are easy to use on a daily basis.

- Plug and Track designs Plug and Play products, i.e. ready to use.

- We attach great importance to providing you with fast decision-making tools.

- So you can concentrate on the job you love, and meet your legal obligations with complete peace of mind.

How to monitor the temperature in your food production ?

We have developed effective tools to help you master your HACCP approach.

Temperature traceability of refrigerators and freezers

Regularly checking the temperature of your cold rooms and freezers is important. This allows you to check that the raw materials and foods you produce are kept at the right temperatures.

A Thermo Bouton temperature datalogger allows you to secure the cold chain by continuously recording the temperature. You save time by printing the temperature graphs and keeping all your data on your computer with the Thermotrack PC software.

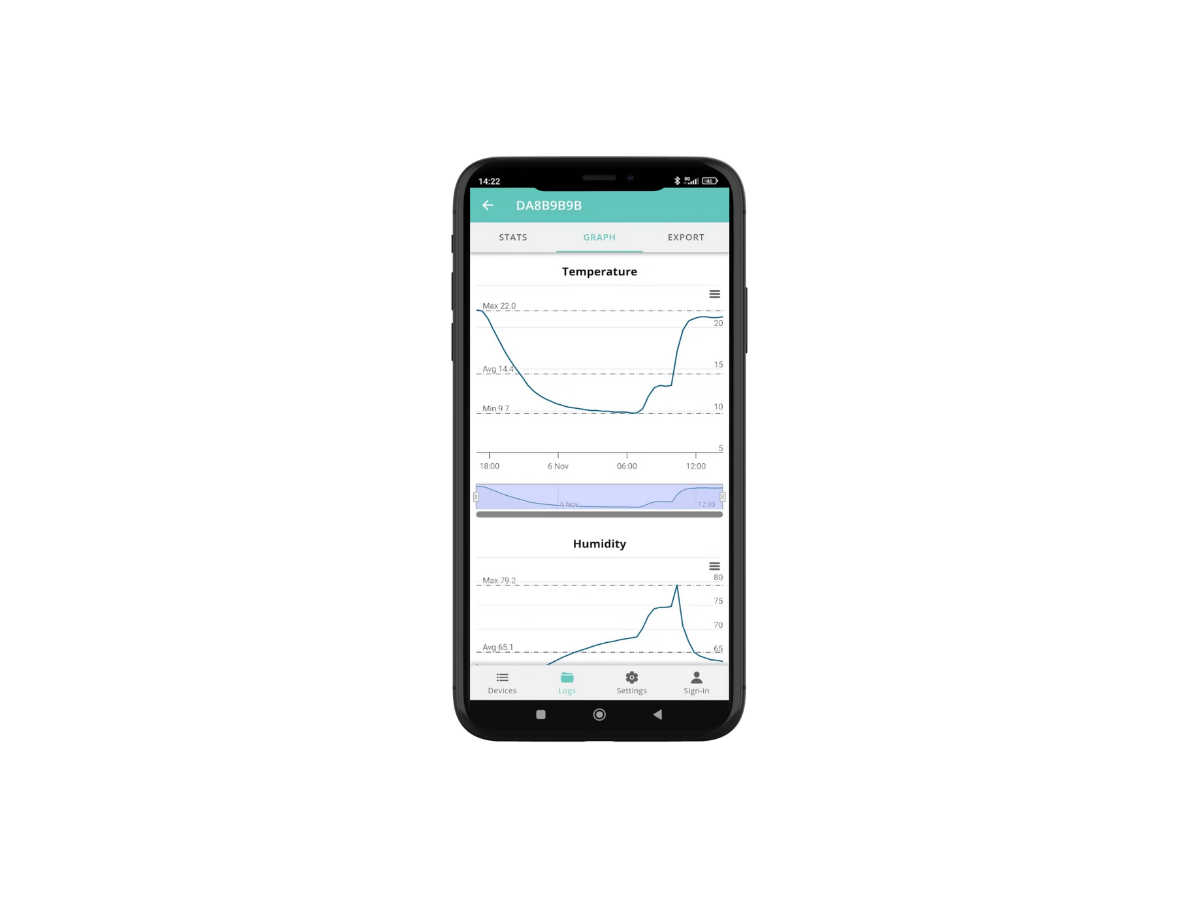

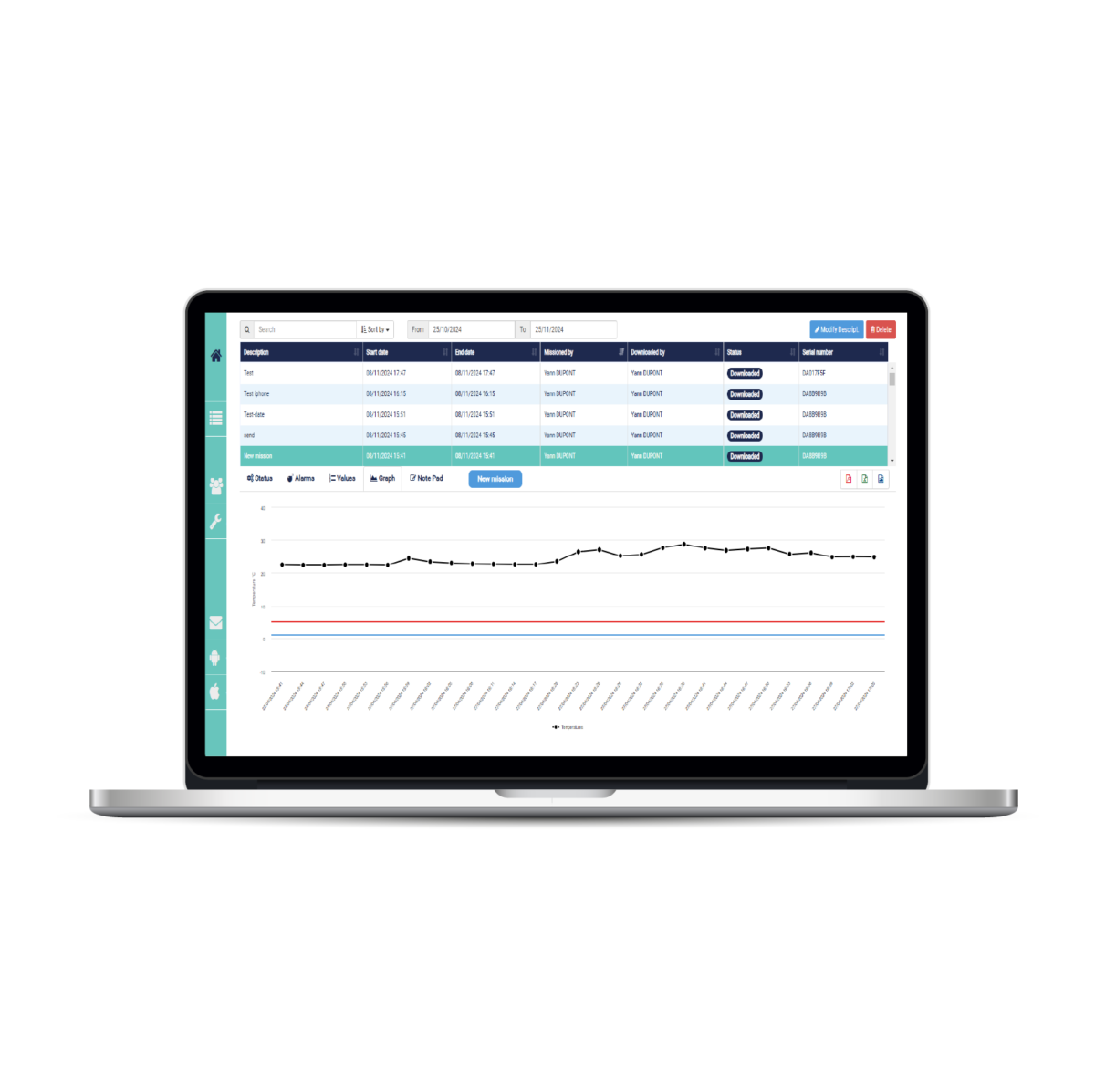

Real-time temperature monitoring

If you are looking for an alarm system via SMS or Email when your cold rooms, refrigerators or freezers are outside the normal temperature ranges, we have what you need. Our temperature sensors are accurate. Wireless, Wi-Fi or Ethernet sensors on your computer network, they are easy to install. You can then monitor your equipment remotely from your phone, computer or tablet.

Thermotrack Webserve’s free Manual Reading System also allows you to ensure that daily checks are done in all your establishments.

Temperature control of meals in hot and cold state

If you are a foodservice specialist, you know that controlling the temperature of meals served at school, university or health care facilities is essential.

It’s a guarantee of quality. It is important to ensure that rapid cooling between 63°C and 10°C is achieved in less than 2 hours. When re-warming, you must go from 10°C to 63°C in less than one hour.

To make your controls easier, you can use the ThermoBuzz which records the temperatures and warns you as soon as the desired temperatures are reached.

For deliveries, whether in refrigerated vehicles or in food distribution trolleys, you can use a Thermo Bouton to record the temperature from end to end.

Validation of sterilization and pasteurization schedules

Heat treatment, sterilization, pasteurization allows to preserve food. It ensures microbial destruction (microorganisms and spores for sterilization).

To validate your sterilization or pasteurization, we offer you the iBee, a waterproof temperature recorder so that you can carry out your controls at the heart of the product, directly in the can. The Thermotrack PC software will even help you to calculate the F0 (F Zero) sterilization value and the pasteurization value.